Sherwin-Williams presents coatings designed to satisfy the needs of storage tank applicators and asset homeowners for ease of application and longevity. Oil-based paints are extra durable, stain-resistant, and supply an intensive finish. However, they're dearer, susceptible to cracking and chipping, and take longer to dry. On the other hand, water-based paints dry quicker, emit fewer fumes, and are extra resistant to cracking, chipping, and fading.

Often, this contains discussions concerning the surrounding infrastructure and any distinctive challenges from your project. These elements can affect the staffing, scheduling, equipment, and coatings needed for the job. At Markley’s Precision we offer only The Best paint jobs available on the market, which involve sandblasting to a close to white metallic blast spec SSPC SP10 or for the most effective blast a white metallic SSPC SP5. These tanks are then coated with a coat of zinc rich primer, 2 coats of epoxy with a further stripe coat along the welds, and 1 coat of hydroflon polyurethane topcoat. Low high quality paint jobs for a tank typically contain a primary stress wash of the exterior, spot priming areas showing clear corrosion issues, then overcoating with a coat of oil primarily based enamel paint. Typically these paint jobs will final 1-5 years with most averaging 1-2 years.

Industrial Painting Methods for Coating Water, Fuel, and Storage Tanks

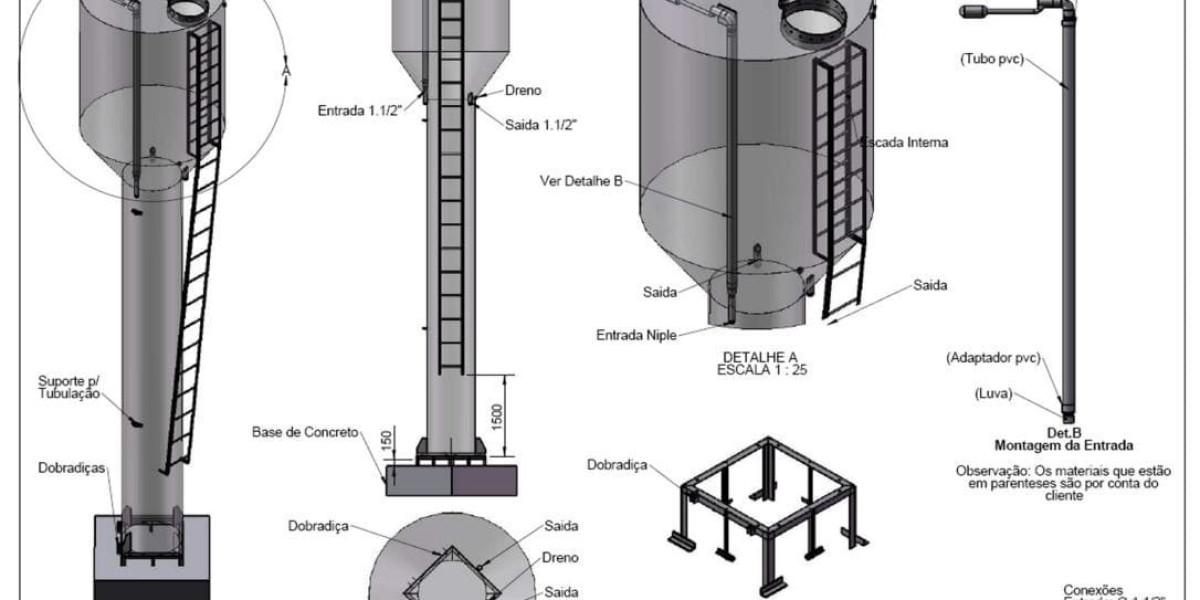

These tanks are handcrafted separately, utilizing a number of the authentic machinery. We value creating sustainable merchandise and whereas time will finally catch as much as every tank, the steel is 100% recyclable. During further consultations, we give you varied options and focus on different equally important elements of the project, such because the timeline, work phases, worth and squareblogs.Net the influence on your business operations. We’ll give you each detail in the final proposal and work with you thru every step of the method till the project is completed. Next, treat any rusty areas with a rust converter, and then prime the tank with an oil-based primer. After eradicating the loose paint and treating the rust, it's important to totally clean the surface of the tank to remove any filth, micro organism, mould, mildew, grease, or different contaminants. You can use a stress washer or energy tools for this step, guaranteeing that you simply clean all areas that will be painted.

Surface Preparation

Our advice for most of our canal boat prospects or boat house owners with comparable tanks can be to wash these tanks as greatest you can eradicating any loose paint and rust. Once clear and dry apply a quantity of coats of our SML Ballastic Epoxy paying particular attention to the perimeters and corners. Then, only use these tanks for laundry up water, bogs and so on and install a smaller accredited plastic water tank with its personal pump for drinking water. By following these steps, you'll effectively prepare the exterior floor of your steel water tank for painting, ensuring that the new paint job shall be long-lasting and aesthetically pleasing. Because this matter can actually be a lot to digest, the American Water Works Association (AWWA) offers quite lots of helpful assets, together with the AWWA D guide for coating metal water-storage tanks. This information covers every thing from pre-construction primer options, to various sorts of inside and exterior coating techniques. For the purposes of this blog post, Section 4.3 for Exterior Coating Systems offers seven coating system choices with mil thicknesses, usually starting from 5.5 to 6.5 mils.

Commercial Painting

Commercial Painting Deterioration and corrosion in industrial storage tanks can let contaminants into your tanks or let liquids seep out. Either means, you presumably can have a big and expensive problem to repair, particularly if you don't catch it shortly. There are several security variables and procedures to contemplate when working with storage tanks. When we first start a project, we start by identifying all Jobsite Hazards going by way of our JSA Forms. Before we start our tank painting process, we all the time verify conditions corresponding to relative humidity, moisture content material, temperature, and dew level to make sure the situations meet coating specification. Repainting your water tank protects it from damage, keeps the water clear, and extends the lifetime of the tank.

Yet, it slowly impacts the tank’s integrity and looks, making it essential to schedule regular upkeep based mostly on how long you’ve had the tank. Left unchecked, it can result in diseases for anybody consuming or utilizing the water. Regular painting and upkeep are key to stopping these dangerous micro organism from taking hold. In addition to bridging gaps, this tape can be used as a sealing wrap, offering a brief answer for leaks in low stress piping.

Storage Tanks

Ferrous metals embody steel, cast iron, and wrought iron, and they are going to be magnetic and susceptible to rust. Non-ferrous metals embrace aluminium, copper, stainless steel, and zinc, and they are often light-weight and malleable. Galvanized metal, which is metal with a thin coat of zinc to forestall rust, must be treated as non-ferrous when painting. In some circumstances, it might even be as simple as a four-component alkyd coating system, with a red oxide or aluminum primer for added corrosion safety. Although usually thought of to be a cost-effective system, it's going to perform exceptionally nicely in an environment that’s not notably corrosive. As such, the tasks can represent or require a major logistical challenge.

Selection of suitable coatings

Your water storage tank might not be in its greatest form when you spot paint beginning to fade or chip away. When rust or cracks start displaying, it screams for a new coat of paint to maintain everything operating easily. Often instances our technicians find gaps round pipe openings and nozzles whereas engaged on a tank lining project. While these gaps don't create leaks or structural issues, filling or coating them can show to be a problem. PLS 755 Tank Tape is a wonderful solution, bridging these gaps and creating a flat and complete surface to line over.